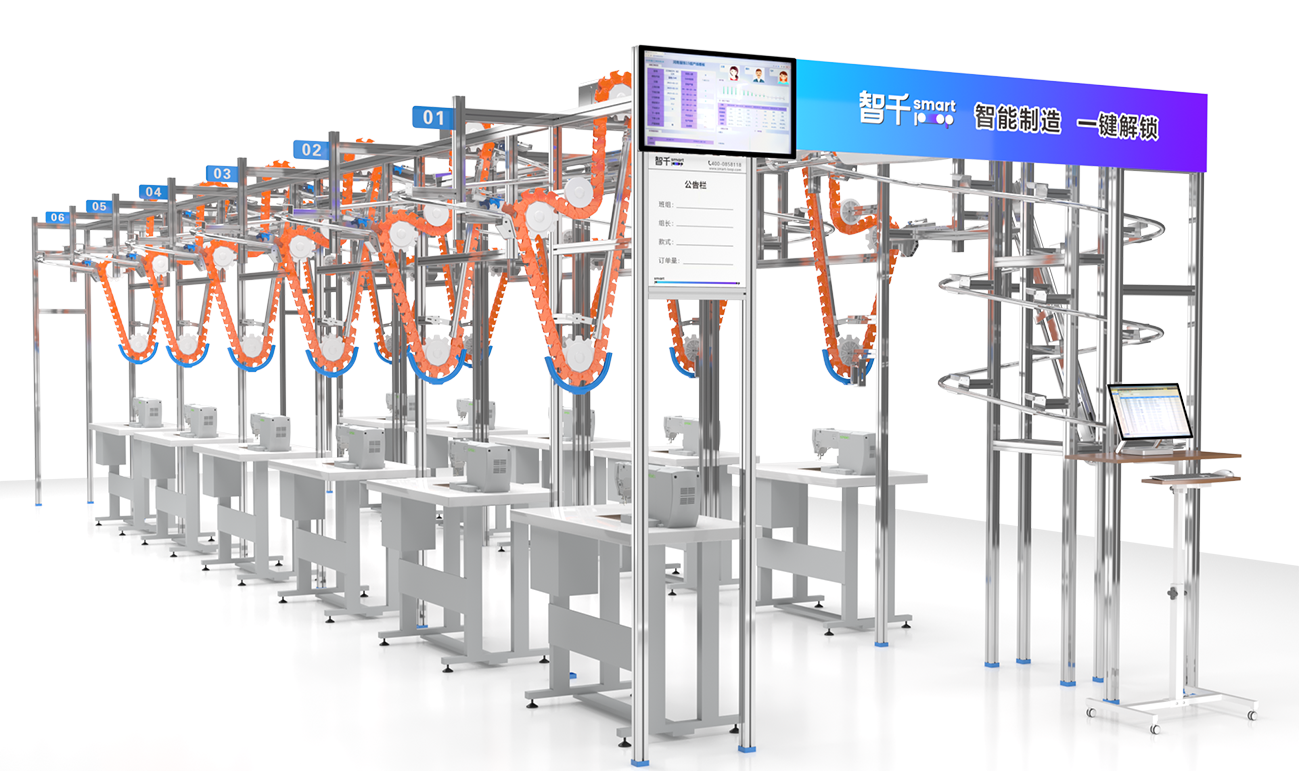

Achieve fully automated workflow from cutting to finished garments in apparel production, significantly enhancing production efficiency and quality.

The Zhiqian Intelligent Hanging System employs advanced RFID technology and automated control systems to enable full-process tracking and intelligent scheduling throughout garment production. The system automatically assigns tasks, balances production lines, and monitors progress, significantly reducing manual intervention and boosting production efficiency.

The system supports manufacturing across multiple garment categories, including shirts, T-shirts, jeans, and down jackets, with flexible production line configurations adaptable to the specific process requirements of different products.

Operating speed:0.8–1.2 meters per second

Workstation spacing:Adjustable from 1.8 to 2.5 meters

Maximum number of workstations:120 per line

Load-bearing capacity:Maximum 5kg per hanger

Through intelligent scheduling and automated workflow, production efficiency has increased by 20–30%.

Reduce non-value-added tasks such as handling and searching, saving over 40% in manpower.

Real-time monitoring of production data enables fully transparent management of the production process.