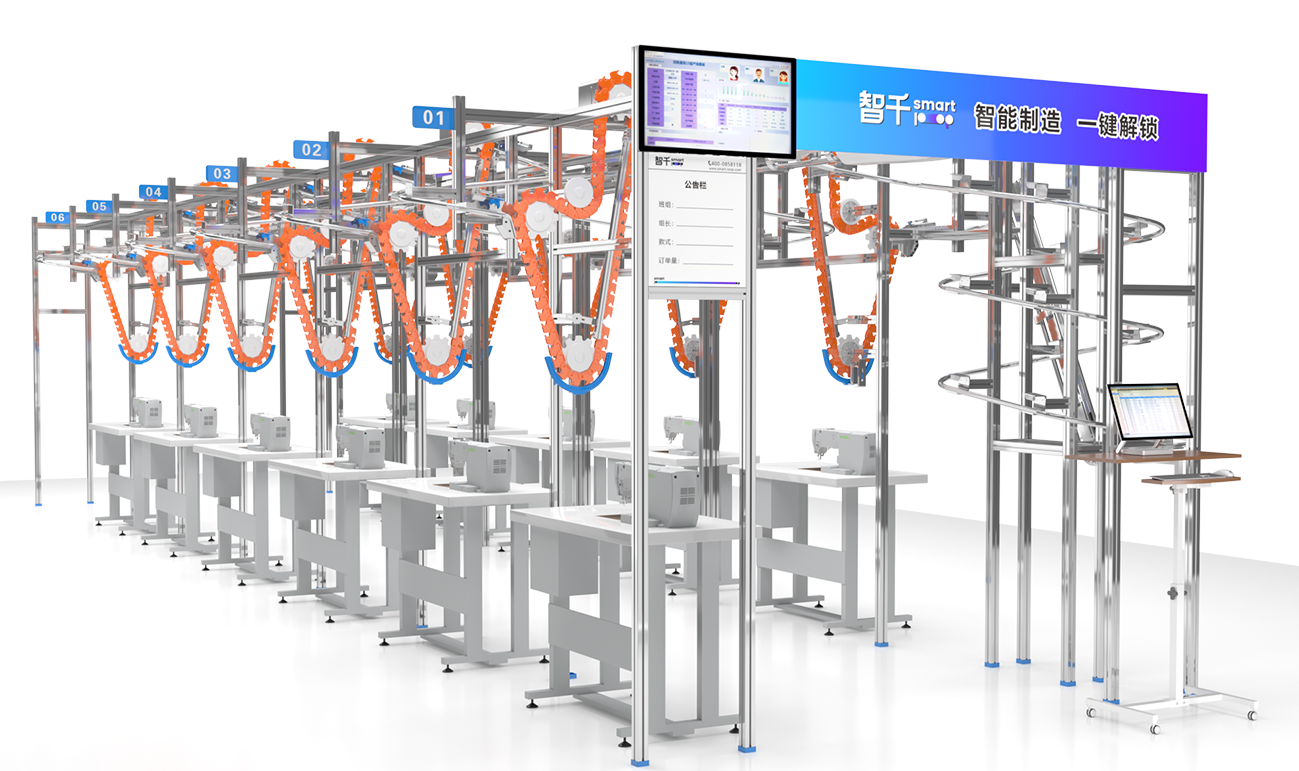

Zhiqian Intelligent is dedicated to providing comprehensive smart flexible production lines and intelligent warehousing and logistics solutions for the apparel, footwear, and luggage industries, empowering enterprises to achieve digital transformation.

Through intelligent hanging systems and flexible sewing lines, we achieve automation, informatization, and intelligent operation of sewing production lines, resolving efficiency bottlenecks and management challenges inherent in traditional production lines.

Achieve automated workflow in apparel production, significantly boosting production efficiency while reducing manual intervention.

√Single-piece flow production reduces work-in-process inventory.

√Real-time Data Monitoring and Production Scheduling

√Automatic balancing production line, eliminating bottlenecks

√Supports flexible production of multiple varieties in small batches

Smart sewing solutions for the footwear and apparel industry, enabling efficient, precise, and flexible production.

√Automated Material Handling and Precision Placement

√Intelligent Process Orchestration and Scheduling Optimization

√Real-time production data visualization

√Supports rapid changeovers and multi-product production

Through intelligent scheduling and automated material handling, production efficiency has increased by 10% to 30%

Monitor production data in real time to achieve production process visualization

Quickly switch production styles to accommodate small-batch, multi-variety production demands

Implementing full-staff quality inspection to reduce defective product rework and enhance product quality

Addressing the challenges of traditional sewing production lines, we provide comprehensive intelligent solutions

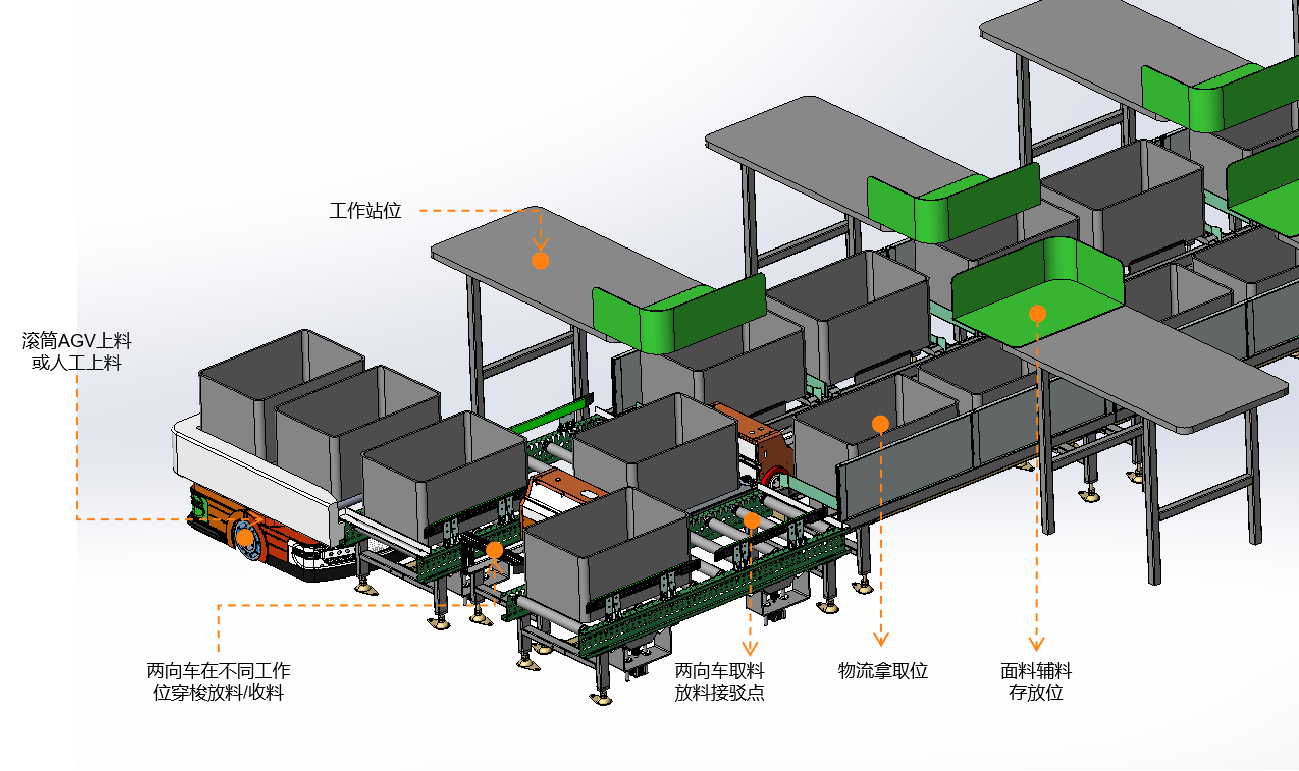

Addressing the issue of inefficient material handling in traditional sewing processes:

Sensor networks monitor the status of carts and material bins in real time

Precision system control ensures materials are delivered to designated processes on schedule

Reduce manual intervention and the potential for errors

Transitioning from traditional manual routing methods to automated system scheduling:

Pre-simulation of optimal trading strategies

Automatically complete scheduling for each process and workstation

Achieve precise material delivery and accelerate production cycle times