Zhiqian Intelligent Flexible Sewing Lines leverage advanced automation technology and smart control systems to deliver comprehensive solutions for sewing production lines.

Our solutions are widely applicable across sewing scenarios including apparel, footwear uppers, luggage, and home textiles, enabling end-to-end intelligent management from material handling and process sequencing to quality control.

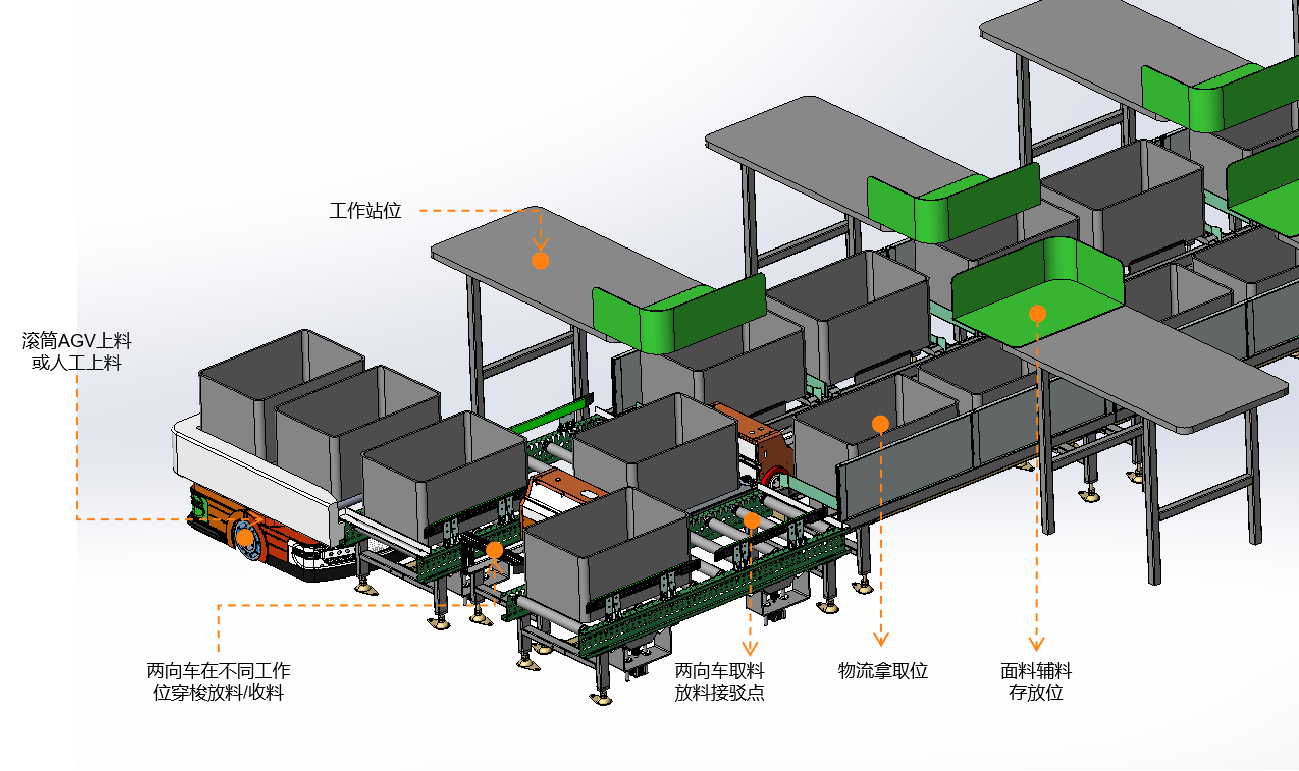

Automated material handling via AGV carts reduces manual intervention and boosts efficiency by over 50%.

Intelligent process orchestration and scheduling optimization, boosting production line balance rate by 30%

Visualize data throughout the entire production process to enable precise management and decision-making.

Supports rapid changeovers to accommodate small-batch, multi-variety production demands.

The Smart Flexible Sewing Line offers innovative solutions to six core challenges in traditional sewing production:

√ Low material handling efficiency - Automated transport via AGV carts reduces manual handling time

√ Inefficient manual process scheduling - System-automated scheduling optimizes production line balance

√ Lack of material transparency - Real-time tracking enables end-to-end process visibility

√ Difficult data collection - Automated production data capture generates multi-dimensional reports

√ Unclear efficiency metrics - Real-time monitoring of process efficiency pinpoints bottlenecks

√ Challenging line balancing - Data-driven adjustments optimize overall output

Through intelligent scheduling and automated material handling, significantly enhance overall production efficiency.

Reduce staffing requirements for non-core positions such as material handling and data entry

Standardized processes and real-time monitoring ensure product quality.

Quickly switch production styles to accommodate small-batch order requirements.