Product Introduction

SP-S913-M/C913-M

Intelligent Template Machine

- SP-S913-M

- SP-C913-M

Advantages

- The intelligent closed-loop sewing system is adopted to monitor sewing operation in real time and to control the sewing operation by means of feedback interaction.

- RFID advanced chip identification technology, easy to use, more rapid and accurate response.

- Using gravity-type rotary hook oil supply technology, which ensures the constant oil supply and the stability.

- Large stroke needle rod mechanism, needle height up to 22mm, enable to use for different thickness of fabrics and fordifferent sewing application.

Advantages

- The intelligent mechanical presser foot has the flexibility of an intelligent control system and the stability of the mechanical structure.

- Using screw rod with motor control, sewing accuracy can reach to 0.1 mm.

- Optional: laser cutting, vibration knife cutting, double screw rods, automatic sewing function

Efficiency

Through computer control, the stitches of the sewing product are stable to the standard and the pattern is exactly the same, which fundamentally changes the sewing process and greatly improves the sewing efficiency and quality.

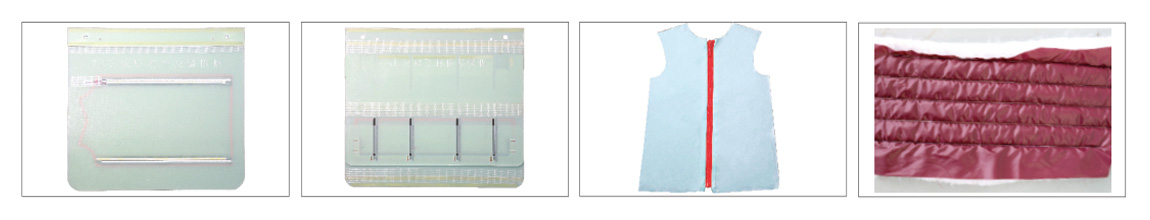

Application

It adopts intelligent closed-loop control system and is good at sewing products with particularly complicated patterns.

Technical Parameters

-

Model

Highest sewing speed

Sewing range

Needle model

Voltage

Air pressure

Weight

Dimensions

-

SP-S913-M3,500 rpm1300×850mmDPx17Single phase 200-240V0.5Mpa、1.8L/min540kg2250×2200×1300mm(L×W×H)

-

SP-C913-M3,500 rpm1300×850mmDPx17Single phase 200-240V0.5Mpa、1.8L/min540kg2250×2200×1300mm(L×W×H)

Download