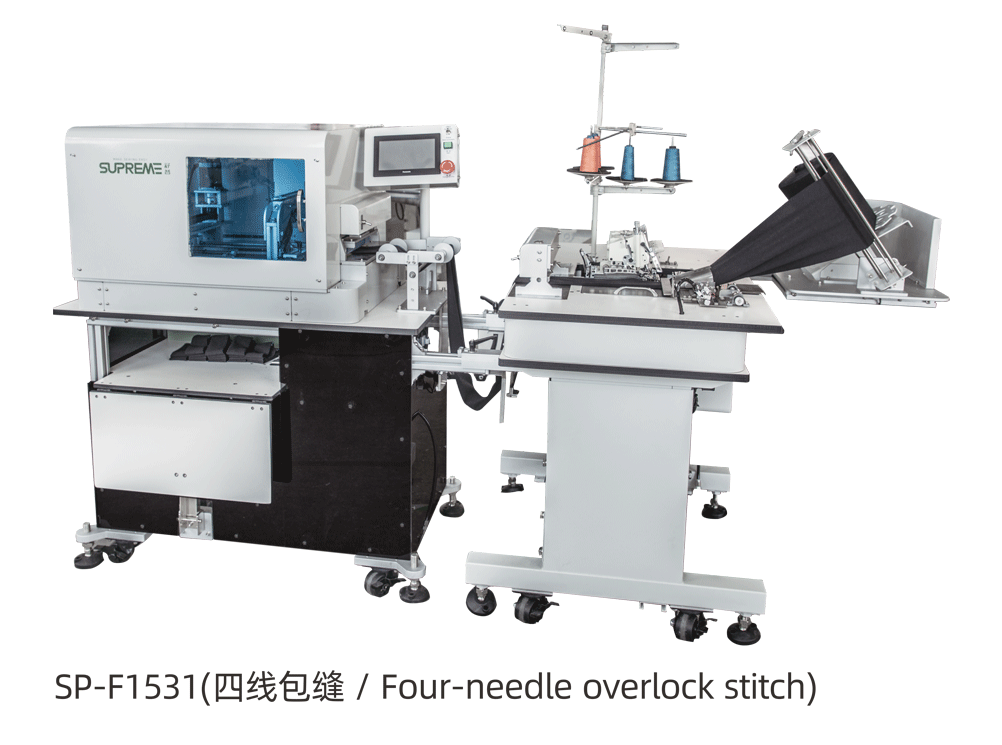

Product Introduction

SP-F1530/F1531

Automatic cuff rib machine

- SP-F1530

- SP-F1531

Advantages

- The operation is simple and does not require senior operator. It integrates multiple clothing craftsmanship and sets them directly on the operation panel. The cutting length and width are accurate, and the whole process is automated.

- With the bottom thread counting function, the receiving and stacking method can be controlled at will. After the upper thread is broken, the equipment will automatically stop the operation and prompt to prevent waste.

- The cuffs or feet of different specifications are adjusted by convenient knobs.

- The panel has a complete fault display function, which is convenient for fault checking and maintenance.

- The tailings collection function setting can prevent the waste of tailings.

Efficiency

- Integrate multiple clothing processes into one, sewing, cutting, threading, turning and receiving are completed at one time, and the entire process is automated.

- The machine occupies a small space and can be operated by one person with multiple machines, 3.5 seconds/piece, 7000~8000 pieces a day.

Application

- It is used for the craftsmanship of cuffs and feet opening.

- Width: minimum 160mm and maximum 360mm (customized according to the size of the trailing puller)

- Length: minimum 100mm (50mm after folding in half) maximum 200mm (100mm after folding in half)

Technical Parameters

-

Model

Highest sewing speed

Stitch

Needle model

Presser foot

Air pressure

Weight

Dimensions

Voltage

Rated power

-

SP-F15304000sti / minSingle needle lockstitch sewingDBX1(#14)CL1/32N0.5Mpa(0.3L/min)300Kg2400×1150×1350mm(L×W×H)Single phase220V900W

-

SP-F15313500sti / minFour needles sewingDCX27Yamato az8020h-y5 four-wire presser pin0.5Mpa(0.3L/min)300Kg2400×1150×1350mm(L×W×H)Single phase220V900W

Download