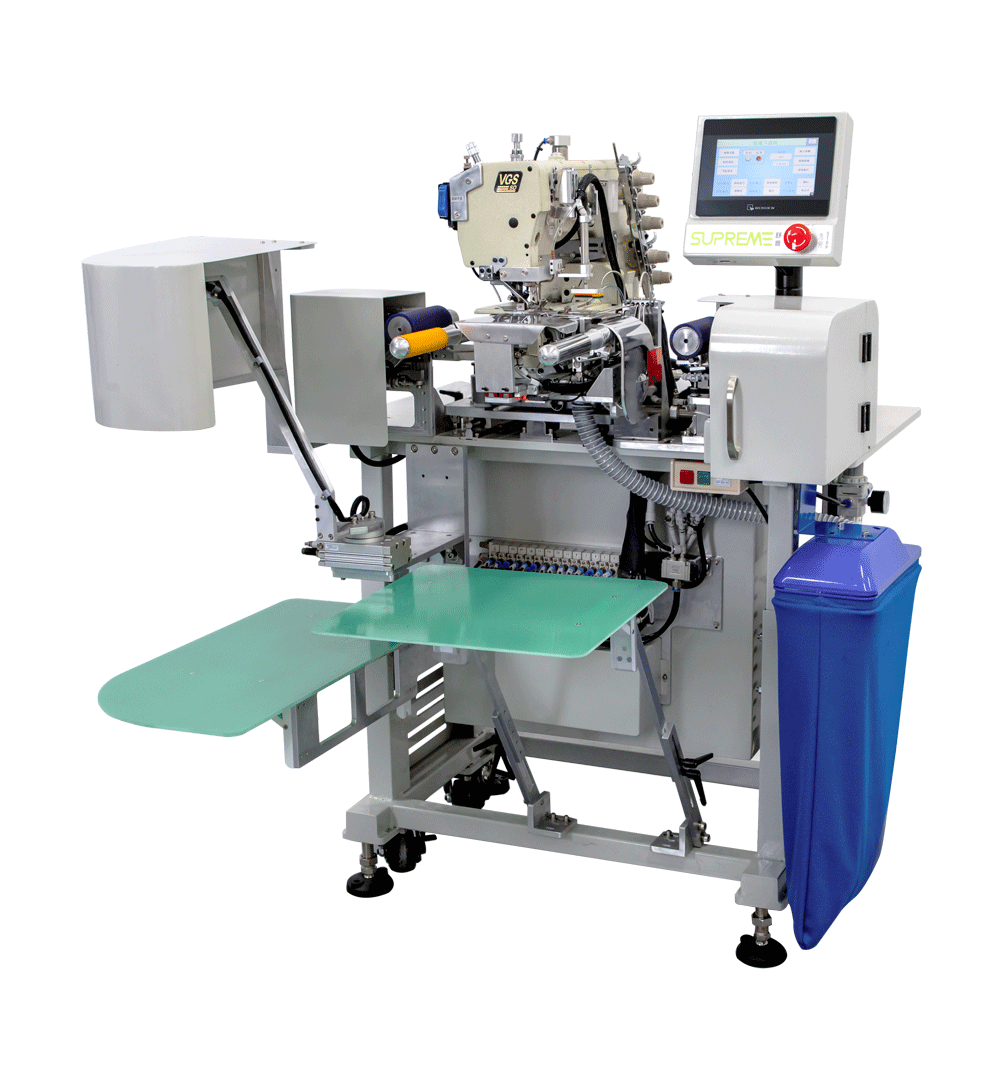

Product Introduction

SP-F217

Automatic interlock bottom hemming machine

Advantages

- Small area occupation ,suitable for a variety of materials(thin material ,medium thick material ,thick material ,high elastic material ),simple setting

- Mixed size clothing :The equiment detects different sizes automatically

- The euqipment folds and stitch the hem after positioning close in designated position

- Automatic guide bone sewing, the direction of the guide bone is the same

- Deviation-correcting guide mechanism: during the sewing process, it automatically senses the margin of the cloth and corrects it in time. The sewing line is uniform, without up and down fluctuations, and the margins from the stitch to the rib are consistent, and there are no undesirable phenomena such as seamoff, wrong edge, etc

- Anti-curling mechanism: solve the problem of inner (outer) roll of clothing, further solve the phenomenon of off stitch, and improve sewing quality

- Supporting mechanism: Reduce margin stitching errors while stitching extra- large size cloth with heavier weight

- Robot Arm Collection: It collects material into the receiving area automatically after sewing process.

Application

Hem folding sewing process of knitted T-shirt,Polo Shirts ,thermal underwear etc.

Download